Extremely thin, hard and fit – high-temperature galvanization has many advantages. It is ideal for small parts, connectors and anywhere where weight and precision play an absolutely key role.

Ocynkownia ŚwidnicaCentrifugal galvanizing

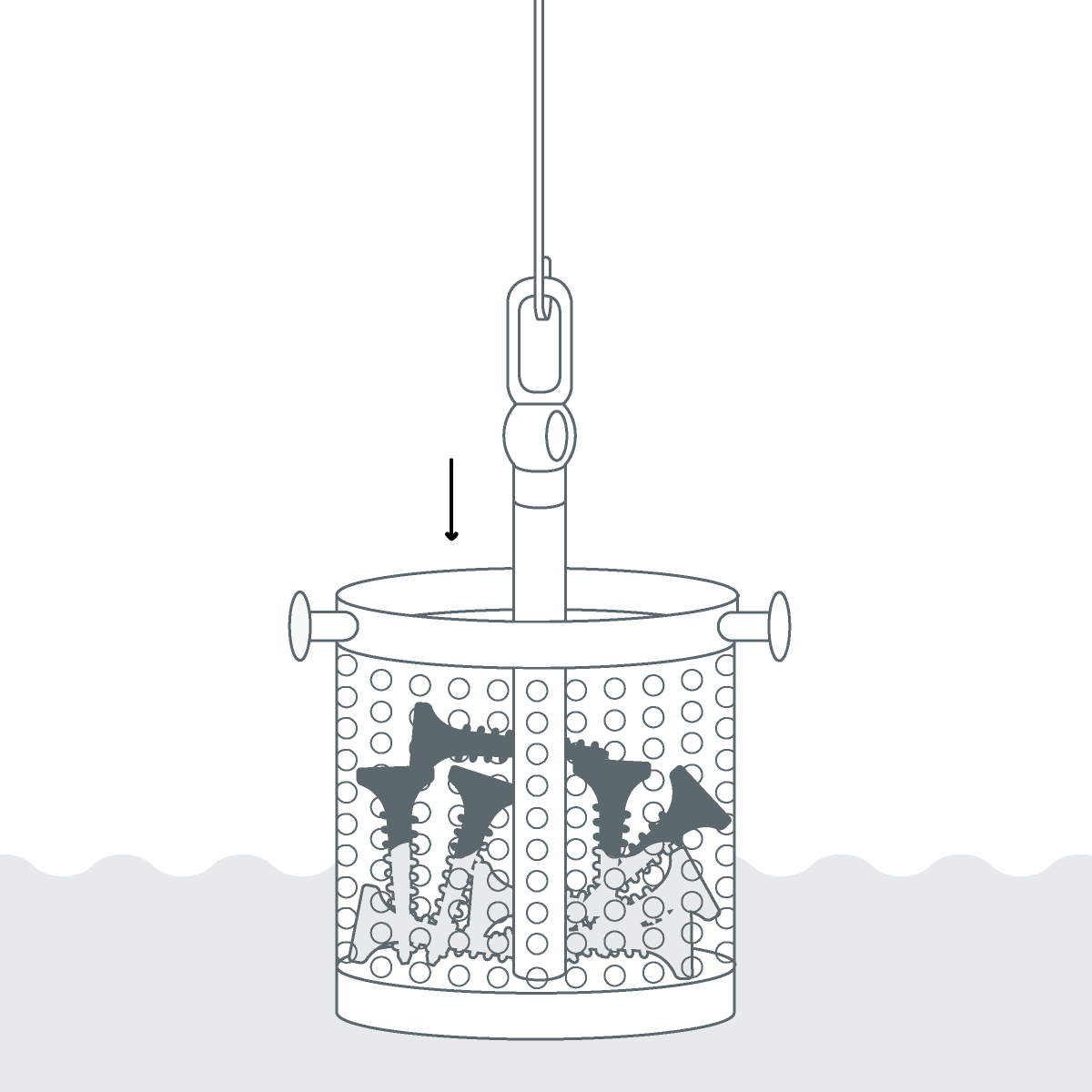

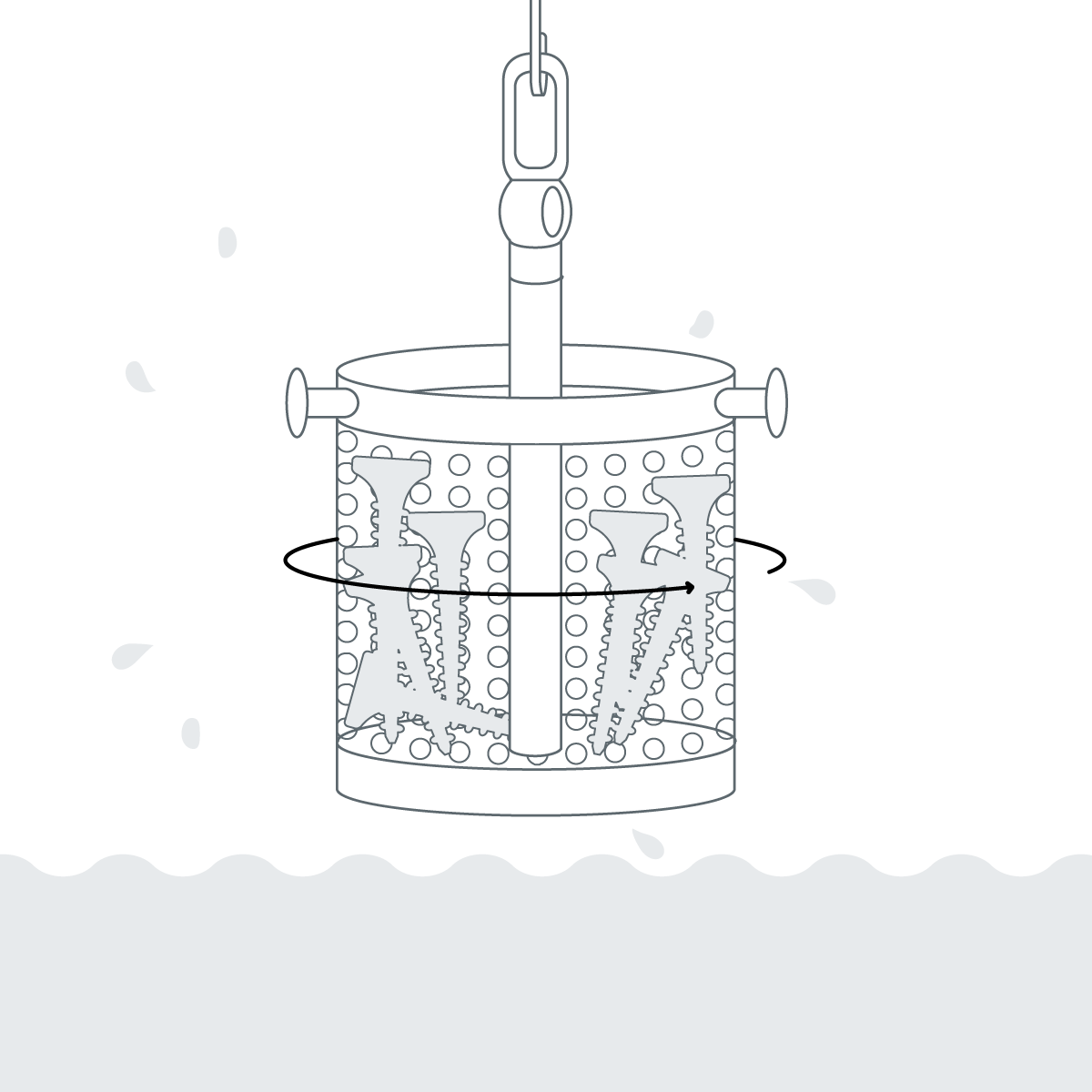

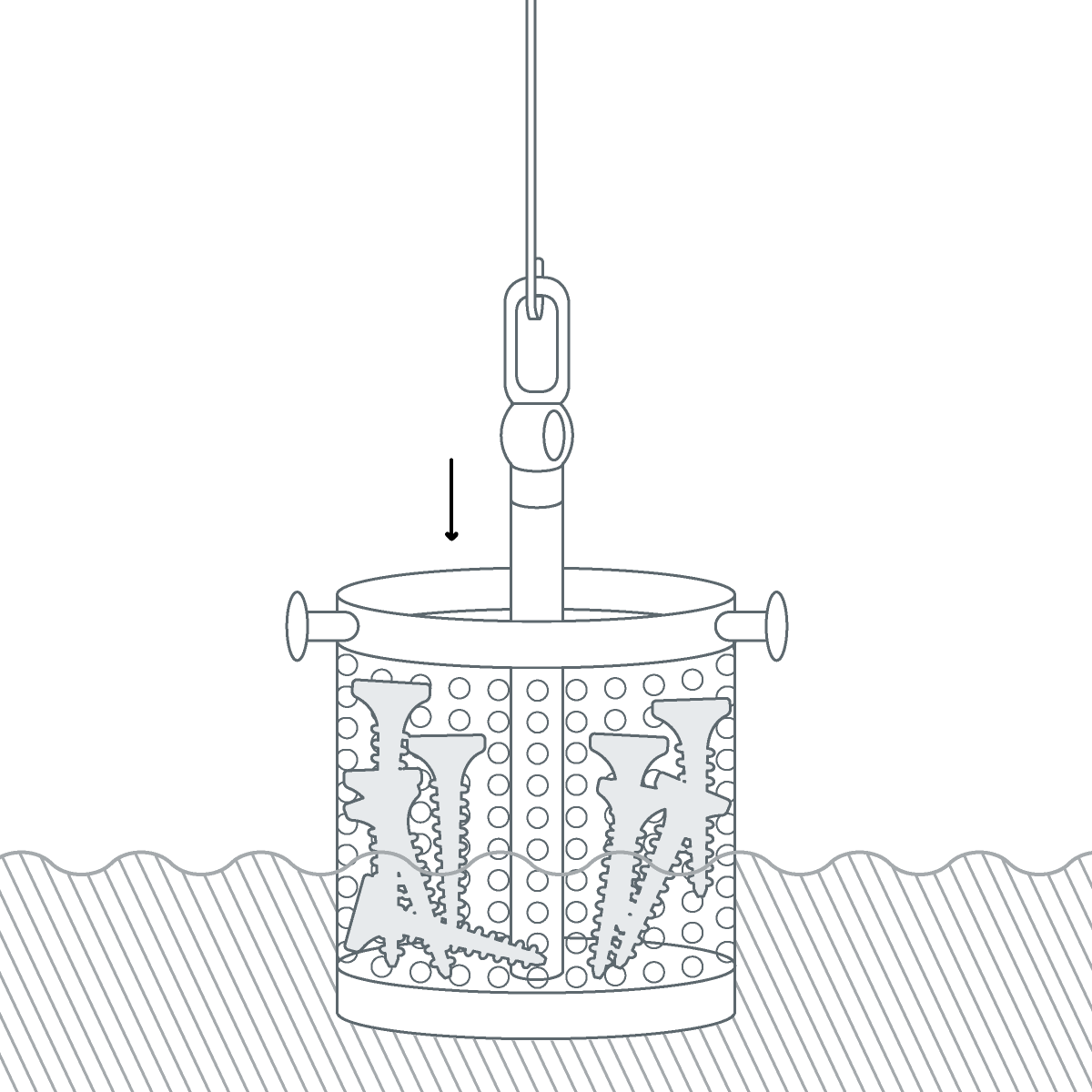

High-temperature galvanizing, also known as centrifugal galvanizing, is available at the Świdnica Galvanizing Plant, which has a state-of-the-art galvanizing bath with a device that centrifuges excess zinc, which consequently enables an even better fit of the components that are subsequently joined (e.g. hinges, screws and nuts).

The technological processes of low-temperature and high-temperature (centrifugal) galvanizing are very similar. High-temperature galvanizing enables obtaining a coating with high corrosion resistance and uniform structure as well as thickness. This method is used for the protection of steel and cast iron components, where the parameters of zinc layer thickness as well as strength are relevant.