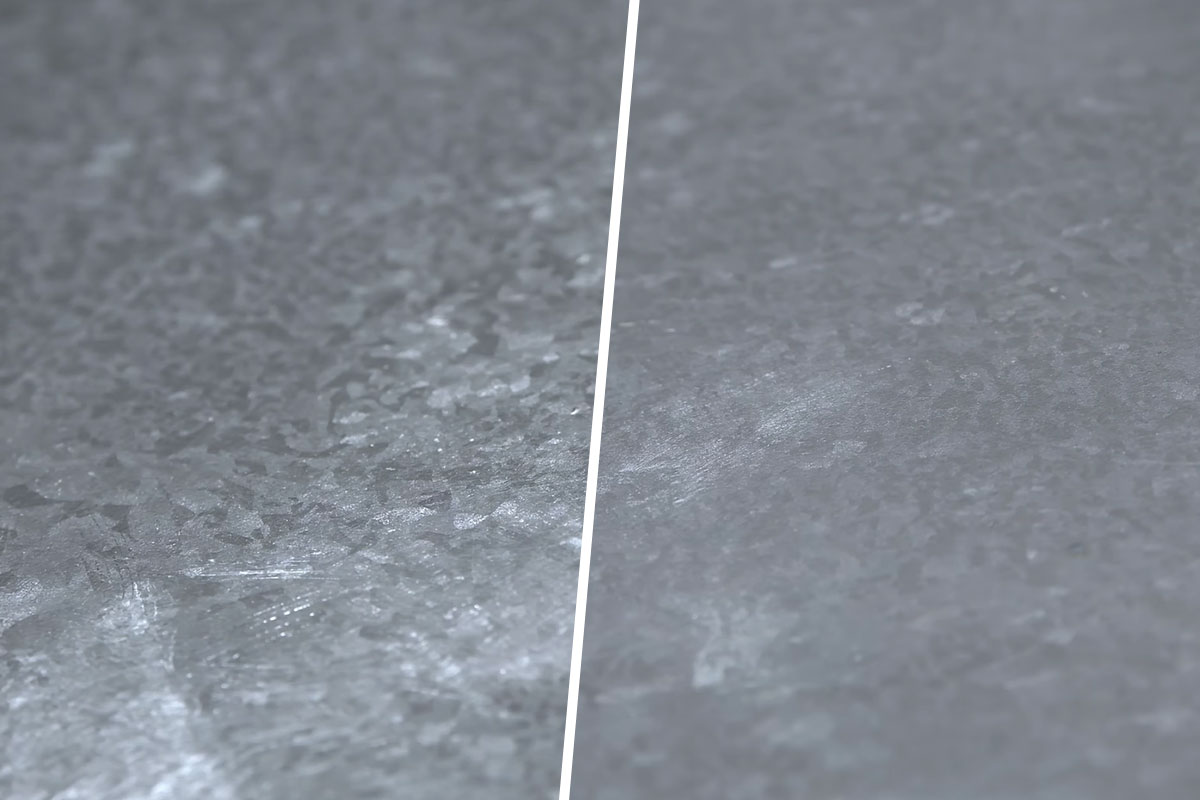

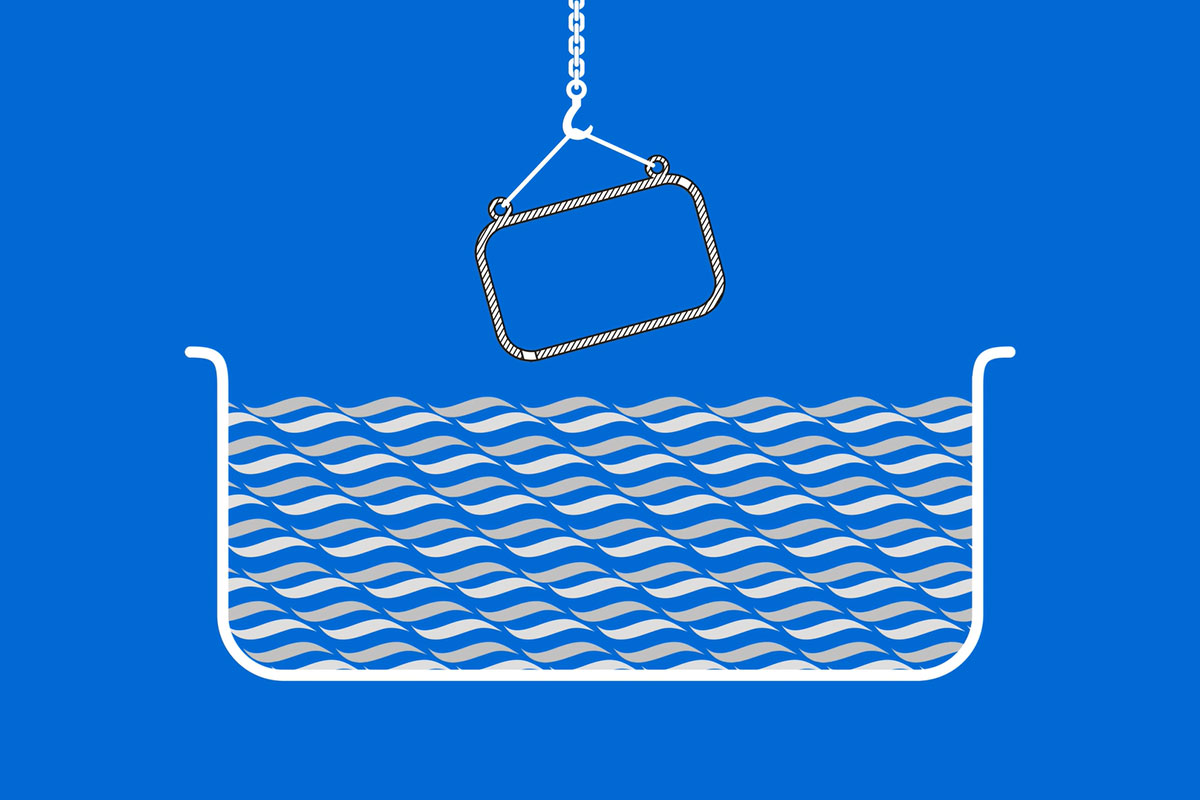

The hot-dip galvanizing process involves immersing steel components in a bath of liquid zinc. As a result of the chemical reaction, an anti-corrosive protective coating in the form of an iron-zinc alloy layer is formed on the steel surface.

The key figures for the galvanizing process is the size as well as unit weight of the component. Thanks to modern production lines, we are able to galvanize a wide range of components, from a 2 cm screw to a 21 m long structure.

Dimensions of galvanizing bathsOcynkownia Śląsk

Seppeler Ocynkownia Śląsk consists of 4 modern hot-dip galvanizing plants. At the galvanizing plant in Chrzanów, we have ensured that you can provide corrosion protection for components up to 21 m in length. The galvanizing plant in Kluczbork is equipped with the widest galvanizing bath in Europe, making it possible to provide corrosion protection for particularly large tanks or containers, but also for other very heavy components. Modernised in 2019 and automated production line of the galvanizing plant in Częstochowa is the most modern galvanizing plant in Poland. It enables the greatest repeatability of parameters, where this is particularly desirable. In addition to the traditional low-temperature galvanizing bath, the galvanizing plant in Świdnica can also protect small components, even of several millimetres in size, during centrifugal high-temperature galvanizing, while maintaining the accuracy of the fit.

Galvanizing plants in Kluczbork and Częstochowa offer, additionally, a passivation service (the so-called cynklar), which enhances the aesthetic qualities of the zinc coating and additionally protects it.

Ask about a price